Effect of Residual Elements on the Mechanical Strength of Recycled Steels

Project PI

Dr. Ramesh Guduru, Assistant Professor, Department of Mechanical Engineering

Short Description

In this project, sponsored by Gerdau Long Steel, a small-scale mechanical testing technique, shear punch test, was built to study the mechanical properties of wire rod steels (produced by Gerdau Long Steel) as a function of their residual content while correlating with their tensile properties and microstructures.

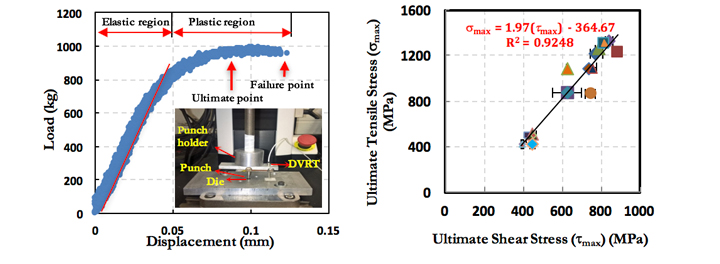

Fig 2: Correlation between ultimate strength and shear stress

Full Description

Production of steel from scrap consumes very less energy and also reduces CO2 emissions when compared with the steel production from ores. However, the problem of recycled steels is the undesired residual elements (e.g. Cu, S, Mo, P, and Ni, etc.), which are difficult to control during the production process. Therefore, understanding the effect of residual elements on the mechanical properties is quite necessary to make sure the quality of steel products from the customer’s point of view.

In this project, a small-scale shear punch test (SPT) setup (see the inset in Fig. 1) was built and utilized for investigating the role of residual elements on the mechanical properties of high carbon steels produced by Gerdau Long Steel plant in Beaumont. SPT is similar to blanking operation, and it is a very useful for determining the mechanical properties, like ultimate strength, yield strength, and strain hardening exponent, etc., especially, when the amount of material is limited.

The shear stress - displacement curve generated during SPT tests resembles tensile curves with the initial linear elastic region and yield point followed by plastic deformation, ultimate point, and the final failure (See Fig. 1). SPT data can also predict tensile properties (See Fig. 2) along with localized variations in the mechanical properties.

In this research, SPT testing of high carbon wire rod steels showed an increasing strength with increasing the amount of residuals. Interestingly, it also showed a changing trend in the strengthening behavior of steels with heat treatment procedures and resultant microstructures in wire rods.

These studies clearly demonstrated the localized nature and quick-to-use advantages of SPT over tensile tests for evaluating the mechanical properties of steel products produced in the industries.

Funding

This project was funded by Gerdau Long Steel.

Publications

Likhith Nalluri, Ramesh K Guduru, Roberto Perez, Leonardo Radicchi S Cunha, Pete Power, Bhaskar Yalamanchili and Thad Boudreaux, “Evaluation of Mechanical Properties of Wire Rod by Shear Punch Test,” Wire Journal International (submitted)(2017)